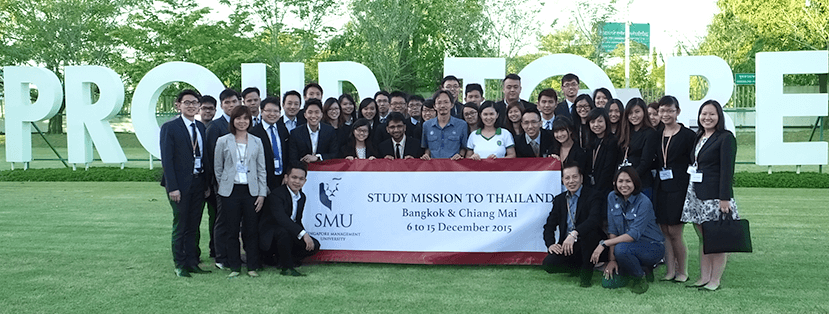

brewery tour

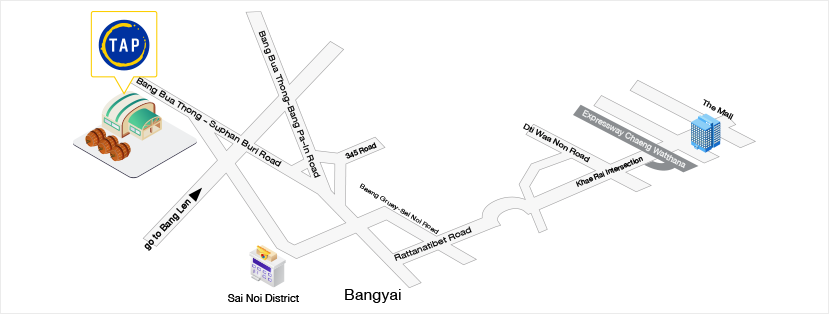

How to Join Brewery Tour

tour hours

- Morning

- Afternoon

- Send your request by email.

- Schedule your preferred date & time for tour at least 2 weeks in advance.

- Confirmation will be sent 1 week after request via email.

- A group of 20 - 40 people is required per group.

- Transportation is on visitors accountability.

- The brewery tour is restricted to over 20's only.

- University student groups are only allowed if accompanied by professor.

please contact Corporate Affairs Department at 0-2246-9734-6 Ext.3205 or Email : brewerytour@tapb.co.th

Brewing PROCESS

over

The ages, the essence of brewing has been Many variables exist in the brewing process, but the quality of ingredients definitely impacts the flavor.

AT TAP

Comprehensive check are carried out selecting raw materials and brewing to taste testing and packaging, each stage is meticulously monitored, ensuring the finest quality brews.

malt

Malt is made from barley. It is full with rich nutrition. TAP uses only the best quality of malt from carefully selected suppliers.

hops

Hops is one kind of vine with green flower. Brewers use this flower in beer to provide aroma and bitterness characteristic to the beer.

yeast

Yeast is an important gradient for fermentation process. It metabolizes sugar and convert it into alcohol and carbon dioxide gas. Each type of yeast gives a unique characteristic flavor to the beer.

water

The quality of water is critical for brewing process. It must be purely clean water with appropriate amount of minerals. The company has used purest water.

Milling Process

At this stage malt is cleaned thoroughly before grining into small pieces.

MASHING PROCESS

Water is added to grounded malt and then heated; allowing the barley starch to be converted into fermentable sugar due to enzymsfrom the malt itself. These malt sugar will dissolveinto the water.

MASHING PROCESS

The mixture of malt and water is carefully filtered to separate spent grain. The remaining liquid is now called “Wort”.

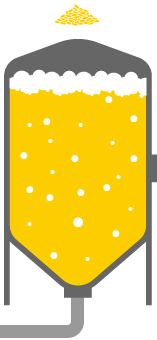

Wort boiling

The hop is added to wort and heated agian to enhance taste and aroma and also to allow a form head to develop.

WHIRLING

The mixture of virgin hops and proteins and wort is whirling to remove hop sediment thereby clearifying the wort. The wort is then cooled and air is added, preparing for fermentation process

FERMENTATION & STORAGE PROCESS

At the proper low temperature, yeast is added to the wort so that the sugar are metabolized by the yeast cells, producing alcohol and carbon dioxide and thus changing the wort to mature beer. The company place vital concern on temperature and time using because they influence the taste and smoothness of the beer.

FILTRATION PROCESS

The mixture of virgin hops and proteins and wort is whirling to remove hop sediment thereby clearifying the wort. The wort is then cooled and air is added, preparing for fermentation process

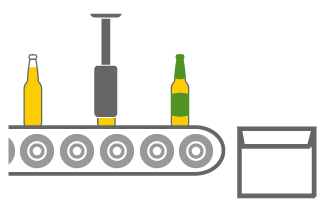

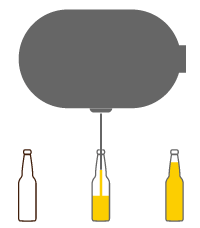

BOTTLE WASHER

All bottle must be washed and cleansed thoroughly with hi-tech mechine to elimenate any dirt and other contaminents before filling. Empty bottle inspector.

BOTTLE WASHER

All bottle must be washed and cleansed thoroughly with hi-tech mechine to elimenate any dirt and other contaminents before filling. Empty bottle inspector.

PASteurizer

All bottle must be washed and cleansed thoroughly with hi-tech mechine to elimenate any dirt and other contaminents before filling. Empty bottle inspector.